xCompare

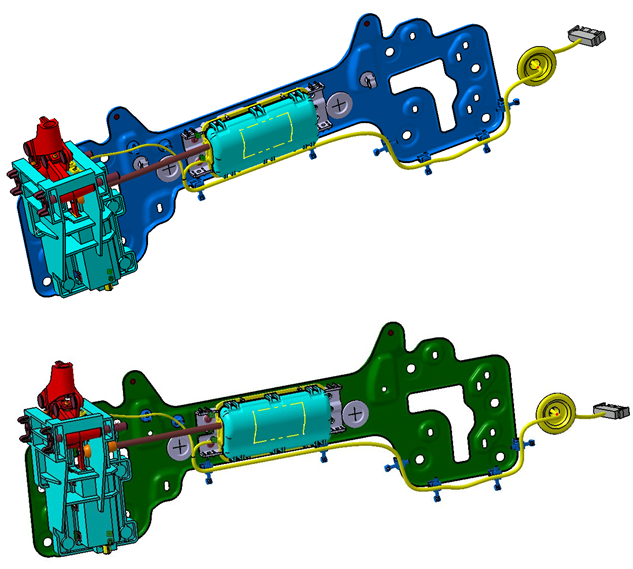

xCompare compares CATIA V5, SMG and JT data, to find differences in two revisions of products, parts and drawings or to verify the conversion process.

In the context of a global collaborative development process, tools helping engineers to handle their complex engineering data are getting more and more relevant. Consequently, a large variety of questions have to be answered. Do my models meet the minimum quality and methodology requirements? What has recently been added or modified in models I work with? Have suppliers modified models from the last release interchanged, and what?

Your Benefits

The following comparisons are currently possible:

With xCompare V5 / V5 users can verify interactively or in batch mode if models – CATParts, CATProducts, CATDrawings and Cgrs – were changed compared to other models. Due to the feature-based comparison, xCompare is not only able to detect geometric differences but also highlights directly the modified CATIA elements. Therefore, modifications that have been made by a supplier, are visible easily for the user. xCompare is fully integrated in CATIA V5 and is available for all V5 platforms.

xCompare V5 / SMG verifies the conversion process from CATIA V5 in SMG (CATIA Composer / 3DVIA Composer), which is very important for downstream process and the long term data archival. Various criteria of a CATIA V5 model are compared to a SMG model. In order to perform this comparison, xCompare uses directly the models to analyse the features as well as the geometry without converting them first into a internal format. Hence, a ensured and reliable verification is guranteed. xCompare V5 / SMG is fully integrated in CATIA.

In many industries CATIA data are translated into different neutral formats to provide downstream processes with the right data. In particular in the automotive industry, CATIA data are converted into the JT format. For some downstream processes it is important to ensure that there are no changes between both data caused by the translator. Unacceptable differences must be found easily before the model moves into downstream.

xCompare is an application to compare CATIA V5 and JT data. Primarily, it is used for the comparison of geometric data – potential nonconformities will be shown graphically. By using xCompare, comparisons of V5 B-Rep with JT B-Rep (JT or XT B-Rep), V5 B-Rep with individual JT LODs (Level of Detail) and V5 CGR data with JT LODs can be performed. The presentation of results is carried out within V5 and will graphically display the differences in geometry. As a matter of course, the results will be saved in XML reports for further documentation. The xCompare V5 / JT solution natively validates the original data format without any kind of translation – so the data remains pristine.

By using xCompare JT/JT, the user is able to verify differences between JT parts or assemblies (PLMXML) interactively or in batch mode within LiteBox3D. Within the configuration, either defined by the administrator or created by the user himself, the specific comparing criteria are determined. Besides the geometric comparison of B-REP and LOD, the detection of structural changes as well as modifications of meta data is also included.

Benefits

Saving time with comparing models

The model comparison can either be performed in CATIA or in batch mode in order to avoid doing it manually.

Increase reliability

A manual verification implies the risk of human errors, since changes can be missed in complex models. xCompare ensures that all modifications are found.

Fulfill legal or company requirements regarding documentation

For data conversion and long term data archival, legal or company internal regulations might require that the generated or archived model data are consistent with the original data of the CAD system. xCompare V5 / JT and V5 / SMG ensure this verification.

Functionality

Traceability of all design changes of CAD models

xCompare compares geometric information such as size, surface area and center of gravity. For meta data, the program checks for example color properties, layers, point and line types and referenced features. By verifying the model structure, xCompare considers elements, attributes and parameters.

Supports CATIA V5, JT and SMG

xCompare V5 / V5 supports CATPart, CATProduct, CATDrawing and Cgr. By using xCompare V5 / JT, a CATIA V5 model is compared with its converted JT model. xCompare V5 / SMG ensures the conversion process from CATIA V5 to the CATIA Composer format SMG.

Support of 3D Master process and Long Term Data Archival

The feature-based comparison detects all design changes including FT&A elements (Functional Tolerancing & Annotation), that play an important role in a drawless process. During the validation of a data conversion, xCompare guarantees that unacceptable differences are not moved into downstream processes and data archival.

Full integration in CATIA or LiteBox3D

All xCompare V5 products are fully integrated in CATIA V5. Thus the V5 models can be read directly using the CATIA CAA interface without model translation. The SMG- and JT-data to be compared are also read with CAA or Technia Transcat own APIs based on the ISO standard 14306:2012. The JT / JT comparison is integrated in the Technia Transcat JT viewer LiteBox3D.

Model comparison using the original data without any conversion

The advantage of applying xCompare is that the original data are directly validated without any prior conversion to a different data format. Consequently, a ensured and reliable verification is guranteed.

Interactive and Batch comparison

The model conversion can be performed interactively in CATIA or in LiteBox3D. In the case of a process integration, the execution can be carried out in batch mode.

Detailed and flexible reports

The user receives a detailed XML report of all changes including graphical illustrations. Furthermore, those reports are adaptable to various stylesheets.