MSC Adams

The Multibody Dynamics Simulation Solution

Adams helps engineers to study the dynamics of moving parts, and how loads and forces are distributed throughout mechanical systems.

Product manufacturers often struggle to understand true system performance until very late in the design process. Mechanical, electrical, and other subsystems are validated against their specific requirements within the systems engineering process, but full-system testing and validation comes late, leading to rework and design changes that are riskier and more costly than those made early on.

Simulate “Real World” Physics

As the world’s most famous and widely used Multibody Dynamics (MBD) software, Adams improves engineering efficiency and reduces product development costs by enabling early system-level design validation. Engineers can evaluate and manage the complex interactions between disciplines including motion, structures, actuation, and controls to better optimize product designs for performance, safety, and comfort. Along with extensive analysis capabilities, Adams is optimized for large-scale problems, taking advantage of high performance computing environments.

Utilizing multibody dynamics solution technology, Adams runs nonlinear dynamics in a fraction of the time required by FEA solutions. Loads and forces computed by Adams simulations improve the accuracy of FEA by providing better assessment of how they vary throughout a full range of motion and operating environments.

Adams Mechatronics is a plug-in to Adams which can be used to easily incorporate control systems into mechanical models. Adams Mechatronics has been developed based on the Adams Control functionality and contains modeling elements which transfer information to/from the control system. For example, using Adams Mechatronics in Adams Car, you can quickly create assemblies of vehicle systems including control systems, and then analyze them to understand their performance and behavior.

- Add a sophisticated controls representation to your Adams model

- Connect your Adams model to block diagram models you’ve developed with control applications such as Easy5® or MATLAB®

- Experience flexibility in simulation styles to suit your problems’ needs: simulate within Adams, within the controls software or co- simulation

- Access advanced pre-processing for Adams Controls

- Setup and couple a control system to a mechanical system

- Convert signal units automatically

- Connect transducer and actuator signals to the control systems easily

- Conveniently review and modify the control system input and output specifications

- Ideal for complex integrations

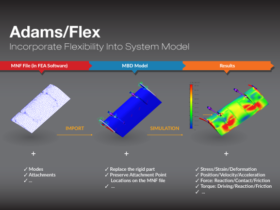

Adams Flex provides the technology to correctly include a component’s flexibility even in presence of large overall motion and complex interaction with other modeling elements. Greater emphasis has been placed these days on high-speed, lightweight, precise mechanical systems. Often these systems will contain one or more structural components where deformation effects are paramount for design analyses and the rigid body assumption is no longer valid. Adams Flex allows importing finite element models from most major FEA software packages and is fully integrated with Adams package providing access to convenient modeling and powerful post-processing capabilities.

- Integrate FEA-based flexible bodies into your model

- Better represent structural compliance

- Predict loads and displacements with greater accuracy

- Examine the linear system modes of a flexible model

- Broad and convenient control over modal participation and damping

Durability testing is a critical aspect of product development and issues discovered late in the development cycle lead to project delays and budget overruns. Worse yet, “in service” failures lead to dissatisfied customers, safety issues, and warranty costs. Adams Durability allows engineers to assess stress, strain or life of components within mechanical systems to design products to last. Direct access to physical test data in industry-standard file formats enables engineers to use loads data captured during tests, and to easily correlate simulation and testing results.

- Shorten your development cycle, reducing costly durability testing

- Provide direct file input and output in RPC III and DAC formats to reduce disk space requirements and improve performance

- Perform modal stress recovery of flexible bodies within Adams

- Export loads to popular FEA software including MSC Nastran for detailed stress analysis

- Integrate with MSC Fatigue to do component life prediction

With Adams Vibration, engineers replace physical tests on shaker devices with virtual prototypes. Noise, vibration, and harshness (NVH) are critical factors in the performance of many mechanical designs but designing for optimum NVH can be difficult. Adams Vibration allows engineers to easily study forced vibration of mechanical systems using frequency domain analysis.

- Analyze the forced response of a model in the frequency domain over different operating points

- Transfer your linearized model from Adams products to Adams

- Vibration completely and quickly

- Create input and output channels for vibration analyses

- Specify frequency domain input functions, such as swept sine amplitude/ frequency, power spectral density (PSD), and rotational imbalance

- Create frequency-based forces

- Solve for system modes over frequency range of interest

- Evaluate frequency response functions for magnitude and phase characteristics

- Animate forced response and individual mode response

- Tabulate system modal contributions to forced vibration response

- Tabulate contribution of model elements to kinetic, static, and dissipative energy distribution in system modes

- Specify direct kinematic inputs

- Plot Stress/Strain frequency response functions

A Powerful Simulation Suite for Mechanical Drive Systems

Evaluate and manage the complex interactions relating to motion, structures, actuation, and controls to better optimize product designs for performance, safety, and comfort.

Build functional virtual prototypes of machinery components and systems early in the design cycle, so you can perform a series of virtual tests before committing to building a physical prototype. With this new solution, machinery manufacturers will reduce the number of prototypes, decrease the design cycle and meet their functional specifications in less time.

Adams Machinery is fully incorporated inside the Adams View environment. It contains multiple modeling productivity modules which enable users to create common machinery components much more rapidly than with generic standard Adams View model construction functionality alone.

Ease of Use

Adams ribbon-style interface and model browser makes it easy for even novice users to create complete, accurate mechanical models. A core package (Adams View, Adams Solver, and Adams PostProcessor) allows you to import geometry from most major CAD systems or to build a solid model of the mechanical system from scratch. You build a system the same way you build a physical system – by creating and assembling parts, connecting them with joints and driving them with motion generators and forces.

High Productivity

Adams Machinery enables users to create some common machinery components more efficiently by guiding users in pre-processing via automation of activities like geometry creation, subsystem connections, etc. It also assists users in post-processing by providing automated plotting and reporting for commonly desired output channels.

Real Dynamics for Vehicle Design and Testing

With Adams Car vertical products, engineering teams can quickly build and test functional virtual prototypes of complete vehicles and vehicle subsystems. Working in the Adams vehicle vertical environment, automotive engineering teams can exercise their vehicle designs under various road conditions, performing the same tests they normally run in a test lab or on a test track, but in a fraction of time.

- Analysis of suspension, steering and full-vehicle maneuvers

- Easy integration of control systems into vehicle models

- Creation or import of component geometry in wireframe or 3D solids

- Extensive library of joints and constraints to define part connectivity

- Model refinement with part flexibility, automatic control systems, joint friction and slip, hydraulic and pneumatic actuators, and parametric design relationships

- Comprehensive linear and nonlinear results for complex, large-motion designs

- Comprehensive and easy to use contact capabilities supporting 2D and 3D contact between any combination of modal flexible bodies and rigid body geometry

Adams allows you to create flexible parts conveniently even in the presence of large overall motion and complex interaction with other modeling elements.

Engineers can incorporate a linear flexible body, as well as nonlinear flexible parts to solve problems involving large deformations and material nonlinearity.

Linear Flexible Parts:

Adams Flex

Adams Flex allows importing finite element models from most major FEA software packages and is fully integrated with Adams package, providing access to convenient modeling and powerful post-processing capabilities. Replacing some key rigid components with flexible parts will increase the accuracy for load prediction.

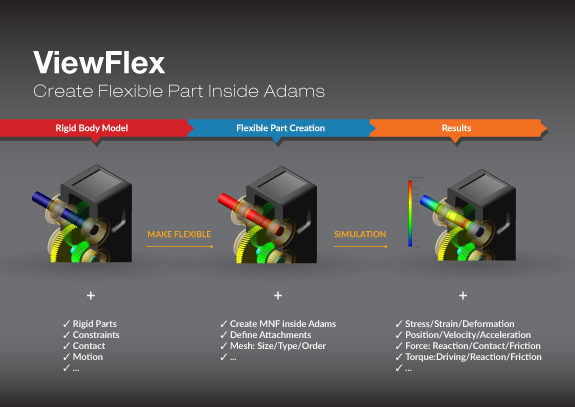

ViewFlex

The ViewFlex module in Adams View enables users to transform a rigid part to an MNF-based flexible body within the Adams environment using embedded finite element analysis where a meshing step and linear modes analysis will be performed. It is powered by MSC Nastran, allowing one to create flexible bodies without leaving Adams View and without reliance on 3rd party Finite Element Analysis software. Also, it’s a streamlined process with much higher efficiency than the way users have traditionally generated flexible bodies for Adams in the past.

Nonlinear Flexible Parts:

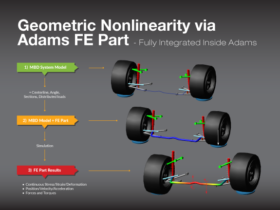

FE Part – NEW

The FE Part is a wholly Adams-native modeling object which has mass and is accurate for very large deformation cases (that is, geometric nonlinearity) of beam-like structures. It provides a fast way to model geometrically nonlinear parts in system model.

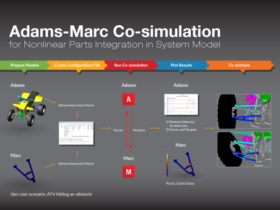

Adams-Marc Co-simulation

The Adams-Marc Co-simulation enables users to perform real co-simulation between world-class Marc nonlinear FE technology with world-class Adams MBD code. With that, MBD engineer can increase model accuracy by including non-linear structural behavior. It’s especially beneficial for applications involving high deformation of viscoelastic materials. Re-meshing can be required using this co-simulation.

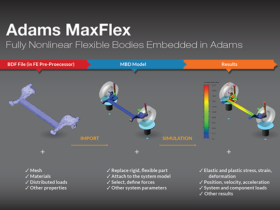

Adams MaxFlex

Based on the implicit nonlinear finite element analysis, Adams MaxFlex allows for the representation of geometric nonlinearity (i.e., large deformations), material nonlinearity, and boundary condition nonlinearity in Adams models. While FEA technology is used to represent and solve the nonlinear flexible body, it is embedded wholly within Adams, so no additional FEA software is required to solve the model.

Maximize Nonlinear Flexibility in Multibody Dynamics Simulations

The Need for Higher Fidelity Simulations

Greater emphasis has been placed in recent years on high-speed, lightweight, precise mechanical systems. Often, these systems will contain one or more structural components for which deformation effects are paramount for design analysis. In those cases, including the flexibility for those key components results in a more precise loading prediction and improved system performance prediction.

Traditional Approaches to Flexible Bodies in Adams:

Adams Flex has been used by Adams users for many years to include linear flexibility into multibody dynamics systems, and allows one to capture relatively small deformation of flexible components (up to roughly 10% of the characteristic length) during a simulation.

However, when it comes to components with geometric or material nonlinearity, like the twist beam in a suspension system or engine mounts, Adams Flex does not provide the capability to cope with nonlinearity in the simulation.

Hence, to incorporate the nonlinear flexibility into multibody dynamics systems, we have introduced a new methodology/tool for our users – MaxFlex.

MaxFlex allows for the representation of geometric nonlinearity (i.e., large deformations), material nonlinearity, and boundary condition nonlinearity. It is based on implicit nonlinear finite element analysis.

Here’re some of the highlights for MaxFlex:

- Using Adams MaxFlex, an MBD analyst can increase model accuracy by including nonlinear structural behavior

- It’s a streamlined workflow, similar to Adams Flex

- Simulation is conducted entirely in Adams

- There is shared memory parallel (SMP) support to increase simulation efficiency

- Easy to set up models and run simulations

- No third-party tool is needed to generate animations with both rigid and nonlinear flexible parts, since it can be done in Adams/Postprocessor

Hardware-in-the-loop Solution

Real Time computational speed is a pre-requisite when combining software models with hardware components, such as a chassis stability controller, vision / range sensors or a driving simulator (e.g. DiM Driving Simulator by VI-grade). MSC Adams has long been the automotive industry’s tool of choice for vehicle dynamics predictions.

Now, with Adams Real Time, analysts can reuse the same base model for high fidelity off-line simulations, through SIL (Software-in-the-loop) to HIL (Hardware-in-the-loop) and ADAS (Advanced Driver Assistance Systems) applications. This one tool / one model approach has the potential to remove weeks from the typical vehicle development program and save tens of thousands of dollars by eliminating the error-prone model translations between different tools.

Adams Real Time Integrator

The Real Time Integrator in an Adams solver setting that will allow the user to meet the real time operating system requirements. This Integrator ensures that both the Adams simulation speed and the communication interval meet the real time platform/hardware requirements (e.g. driving simulator, or abs controller).

Real Time Analysis on SIMulation Workbench Platform

Engineers need Real Time Simulation to connect with a hardware controller or driving simulator. Adams Real Time users to stay inside of Adams for both high-fidelity (complex model with high accuracy) simulation and real time analysis for hardware-in-the-loop. In this release, Adams Solver supports Concurrent’s SIMulation Workbench® (SimWB) real time modeling environment on the RedHawk™ Linux® operating system.