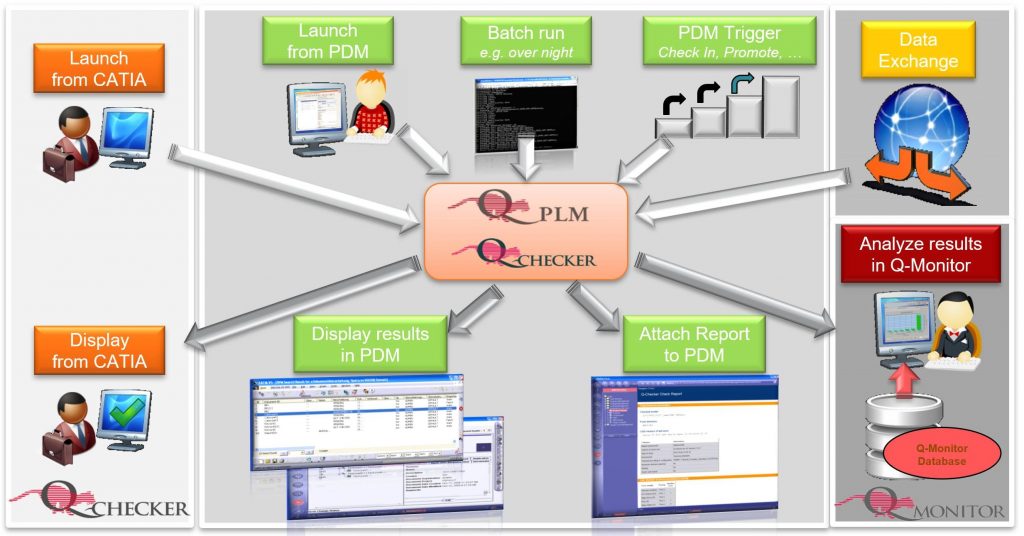

Q-PLM

Q-PLM technology is based on tremendous experience of integrating Q-Checker with an extensive list of PDM systems, including Dassault Systèmes’ ENOVIA SmarTeam; ENOVIA MatrixOne, etc. and data exchange servers such as OpenDXM, TRUfusion and SWAN.

Your Benefits

PDQ as an automated part of the PLM process

Configured with one XML file, it is easily maintained without scripting or programming knowledge.

The later an error is detected in the product development, the more expensive the repair will be. Companies profit to an above-average when implementing Q-Checker in the design phase. At critical points such as the release or gate transfers the product data quality will be ensured.

Q-PLM takes models and process information that are verified by the PDM system or any data exchange processes and carries out Q-Checker batch checks. The results are reported back to process steps in defined formats. Based on those check results a release to the next process step can even be stopped.

Highlights

- Integration of Q-Checker in all PDM systems

- Configuration in one single XML file

- Update of attribute information in the PDM system including an attached report

Benefits

Improvment of model data quality and reduction of repairs by automated checks during the PDM life cycle

Improvment of model data quality and reduction of repairs by automated checks during the PDM life cycle

- Quality information is visible in the PDM system based on PDM attributes and Q-Checker check reports

- Q-PLM offers standard components, that allow a fast and stable integration in the PLM environment

- Low implementation effort

- Compatible with upcoming versions of CATIA and Q-Checker

Funtions

Lifecycle stage

- Check-In: Q-Checker execution before Check- in

- Promote / Release: Q-Checker execution before Release or Freeze

- Workflow: Q-Checker execution upon a workflow task

Assessment scores may be required for better control

- Assessment scores measure the level of quality of a model with a sum calculated by all errors found

- Strict access restrictions can be set so that only clean data is permitted in a PDM system.

- Assessment accuracy can be set regarding to the lifecycle stage

- Message notification is automatically sent to the user/administrator

Different profiles can be run

- A profile is a set of checks used to detect errors within a model

- A profile can be set specifically for PDM quality standards

- Different importance levels can be configured

- Different profiles can be controlled by PDM attributes

Results are communicated clearly inside the PDM system

- With PDM attributes modified by Q-PLM

- With profile tabs automatically populated

- With HTML reports attached to the data inside the product tree